casting impact test|casting volumetric inspection methods : discounter Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Está ocorrendo uma Olimpíada Junior, na qual Patty Pimentinha é coordenadora e há inscritos para todas as modalidades, menos para o decatlo, já que o grau de dificuldade é muito alto e consequentemente ninguém se. Ver mais

{plog:ftitle_list}

Demon Angel SAKURA: The Forbidden Mirror. 3.0.0.1 Kokag.

These test methods cover the details of impact testing apparatus, test specimens, and procedures for cast iron, including gray iron, white iron, malleable iron, ductile iron, and . Charpy impact testing determines the amount of energy absorbed during fracture and involves both ductility and strength. Service load testing can be conducted on an entire . The ASTM standard for impact testing of cast irons covers apparatus, test specimens, and procedures for various types of cast iron. The test methods included in this .

Charpy impact testing is used by investment casting foundries to determine whether an alloy can be classified as ductile or brittle. This information is important for .1.1 These test methods for impact testing cover the details of apparatus, test specimens and procedures for cast iron, including gray iron, white iron, malleable iron, ductile iron, and .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . Impact testing is a test to evaluate the toughness of the casting material by measuring its resistance to sudden shock or impact. This test is performed using an .

Charpy impact testing of castings is a common method of making this determination. Charpy impact testing uses a standard notched sample, which is struck by a .

casting volumetric inspection methods

An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . The keyhole impact test, resembling a machined keyhole, is employed by steel casting industries and follows similar testing procedures as V and U notches. Keyhole impact testing is particularly useful for materials with .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .

EN 10045 Charpy Impact Test for Iron and Steel Castings. This standard can be used for the impact test for cast iron and cast steel materials. Herein, we just list some useful information for iron foundries. The test consists of breaking by one blow from a swinging pendulum, a test piece notched in the middle and supported at each end.

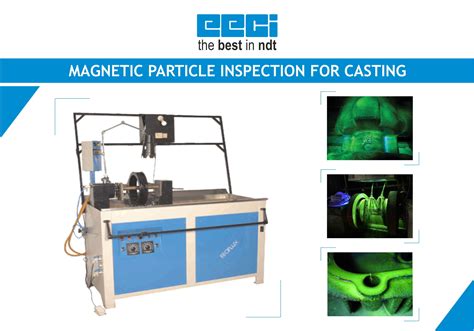

casting particle inspection methods

Tensile and impact testing is conducted on test specimens of standardized dimensions. These specimens may be cut from special test coupons produced as part of a casting or from cut specimens taken from selected castings set aside for destructive mechanical testing. Tensile and Charpy impact are the two most common types of mechanical testing.ASTM A327 provides the standard test method for determining the impact testing of cast iron. It includes two test method s, “Method A: Round bar Charpy-type impact test for gray and white irons”, and “Method B: Standard Charpy-type impact test for malleable and ductile irons”. .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its behavior under sudden loading. This test is crucial in assessing the suitability of materials for applications .

%PDF-1.3 %âãÏÓ 295 0 obj > endobj xref 295 19 0000000016 00000 n 0000002642 00000 n 0000002708 00000 n 0000002960 00000 n 0000003590 00000 n 0000003627 00000 n 0000003857 00000 n 0000004434 00000 n 0000004774 00000 n 0000008385 00000 n 0000008609 00000 n 0000009174 00000 n 0000009618 00000 n 0000015125 00000 n .temperatures. Cast steel offers the mechanical properties of wrought steel and can be welded. Design Impact Casting offers freedom of geometry, so casting part design plays a key role in mechanical performance. Sections of a cast part subject to higher stress can be beefed up while low stress regions can be reduced. This flexibility

TEST COUPONS AND CASTING PROPERTIES The mechanical test requirements for castings are given in the material specification in ASTM. Examples would be impact properties for grade LCC in A352, tensile strength requirements for grade 4N in A487, or ductility minimums for grade 70-40 in A27. The properties were developed for these alloy gradesBased on the ASME impact test requirement, you need to make assessment to see that either your pressure vessel is exempted from impact testing, or you need to carry out the test. There are 4 steps for impact test exemption assessment. You need to know these steps.Impact Testing most commonly consists of Charpy and IZOD Specimen configurations. specimen types include V-Notch, U-Notch, Key-Hole Notch, . machinery component, forged, and cast steel applications. For complete information on ASTM E208, go to www.astm.org . ASTM E604 ASTM E604 - 15 Standard Test Method for Dynamic Tear Testing of Metallic .

bottled water testing at home

The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of engineering materials. Engineers test the ability of a material to withstand impact to predict its behavior under actual conditions. Many materials fail suddenly under impact, at flaws/cracks or notches. The most common impact tests use a swinging .The casting method of the blank test bar, the technical requirements of the impact specimen, the technical parameters of the impact testing machine, the test conditions and methods should meet the requirements of GB6296-1986 "Impact Test Method for Gray Cast Iron".

ImPACT is a computerized concussion assessment tool for ages 12-59. By comparing baseline and post-injury ImPACT test results, you can make confident treatment decisions.The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica-tion, and the customer requirements. After process of elimination, there are often only a few options left. . industry to assess the hardness and quality of cast materials, such as cast iron, aluminum alloys, and bronze. It .ImPACT Applications, Inc., a Riverside Insights® company, is the maker of ImPACT, ImPACT Pediatric, and ImPACT Quick Test, all FDA cleared medical devices that assist in the assessment and management of concussion. See our milestones here and access our press releases here.

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the . In addition, impact tests are also allowed on a WCC casting at -46°C/-50°F to qualify it for low temperature service. This would then be a full-fledged WCC casting qualified for use down to -46°C/-50°F and minus the explicit 345°C/650°F maximum .Impact testing helps assess the fracture resistance and durability of nickel-based alloys under extreme conditions. Various types of cast iron may undergo impact testing to evaluate their fracture behaviour and shock resistance. Impact testing is particularly important for assessing the suitability of cast iron components in machinery and . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

bottled water testing canada

Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, the curve in Figure 323.2.2A of ASME B 31.3 . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer. Impact Test. A hammer of a certain weight strikes or falls on the casting on this test. A defective casing will fail due to the impact of the hammer’s blow. However, this is a very unreliable and crude inspection method. Pressure Test. This type of test is conducted on castings that need to be leak-proof. The castings openings are all closed .a test day and ended with the end of testing. Actual test specimens used for impact testing did not have any thermocouples attached to avoid deleterious affects. Temperatures of the test specimen or test specimen holder were measured (as was done during baseline temperature testing) using a contî ct thermocouple prior to each impact test to assure

Impact test for detection of defects in the casting is the most crude and unreliable method of non-destructive testing. a) True b) False View Answer. Answer: a Explanation: In the impact test, the casting is subjected to a blow by the help of a hammer of known weight, which basically strikes or falls on the surface of the casting. Defective . Impact Testing of Cast Irons: Understanding ASTM A327M 1. Introduction. Impact testing is a crucial evaluation method to assess the mechanical properties and fracture toughness of materials. In the context of cast irons, including gray iron, white iron, malleable iron, ductile iron, and austempered ductile iron, impact testing plays a .Figure 2: Porosity present in the transverse direction of a cast 347 steel test bar. Impact of Casting Conditions on Grain Size and Structure There are multiple casting conditions that will impact the final grain size of a cast part. These conditions include, the chemistry of the alloy, the pour temperature, the .

casting inspection techniques

webCoroas Caseiras | Fotos Caseiras | fotos de sexo - O Seu Local De Vídeos Pornô & Fotos Amadoras. Carregando. Filmes Brasileiros Porno. Carregando. Xvideos Maduras. .

casting impact test|casting volumetric inspection methods